Physicists Tested a New Eye-Safe Laser Type

American scientists have successfully demonstrated photon pumping of a photonic-crystal surface-emitting laser (PCSEL) with a buried dielectric. This device operates at room temperature and emits light at a wavelength safe for the human eye. This represents a significant advancement in laser technology.

A laser is a device that converts energy into a narrow, powerful beam of light with a precisely defined wavelength. Most semiconductor lasers are made by layering different materials. Usually, the laser beam is emitted parallel to these layers. However, vertical-cavity surface-emitting lasers (VCSELs) emit perpendicularly to the layers. VCSELs are easier and cheaper to manufacture in large quantities, simpler to test for defects, and tend to last longer. Face ID technology is based on such lasers.

However, VCSELs have limitations: their beams often have an elliptical cross-section and significant divergence, so they are only suitable for short-distance applications. They are also limited in power and tend to overheat during prolonged use, which degrades the beam quality. When scanning faces, their power must be limited because their emission wavelength can damage the human eye.

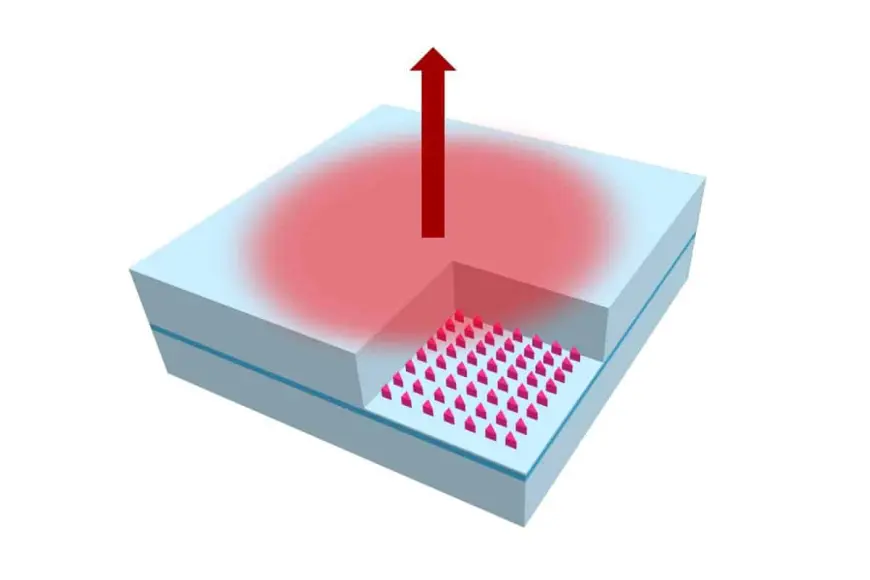

Scientists have found a solution with photonic-crystal surface-emitting lasers (PCSELs). These lasers have a special photonic crystal structure placed above the active region. This addition achieves high brightness, low divergence, and an almost perfectly circular beam profile. Importantly, the emission wavelength (around 1.5 micrometers) is absorbed by the moisture in the eye and does not harm the cornea, making it eye-safe.

Furthermore, PCSELs have the potential to operate at power levels 100 times higher than VCSEL technology.

During manufacturing, PCSEL devices typically contain tiny air pockets where atoms can migrate and disrupt the photonic crystal structure. Researchers at the Grainger College of Engineering at the University of Illinois Urbana-Champaign solved this problem by replacing the air pockets with a dielectric material — silicon dioxide. This prevented structural deformation and stabilized the device.

Their laser operates at room temperature and emits at the eye-safe wavelength of 1.5 micrometers. The research was published in the IEEE Photonics Journal. Improved lasers of this type will enhance lidar technology, autonomous vehicles, laser cutting, and welding. Although still in the lab stage, experts expect industrial-scale production within the next 10 to 20 years.