Grain Harvesting Guidelines

Timely and lossless delivery of the wheat harvest to the national granaries is a responsible task for diligent grain growers. To achieve this, it's essential to adjust combine harvesters and prepare transport vehicles, significantly reducing losses. Wheat harvesting should be conducted promptly within a short timeframe.

According to data, harvesting wheat 15 days after full maturity can result in grain losses of 2–3 centners per hectare. To minimize losses, it's important to assess the amount of grain dropped after the combine passes. A simple method involves using a 1-meter-long rubber hose formed into a ring to count the number of grains inside. If there are 40 or more, the combine's working components need adjustment.

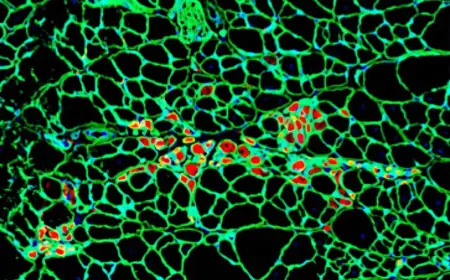

One of the main reasons for reduced seed quality is grain damage during harvesting and subsequent processing. The quality of seeds is influenced by the settings of the combine's threshing mechanism and the grain's moisture content. Damages can be both external and internal, making detection and removal challenging.

Studies indicate that with improper combine settings, the proportion of slightly damaged grains can reach 30–40%, and broken grains can exceed 3%. Large grains are particularly susceptible to damage, while smaller ones remain in the ears and require more intensive threshing.

When seed material undergoes repeated processing, the number of damaged grains increases by 10–15%. Damage to the grain's outer layer reduces its resistance to pests and diseases and negatively affects germination and seedling development. Grain moisture also plays a crucial role: harvesting grain with 10–12% moisture content increases the risk of damage.

Reducing mechanical damage to grain during harvesting and processing helps preserve seed quality, enhances germination rates, and boosts yield.